BU 0055 00060 polyurethane rod seal

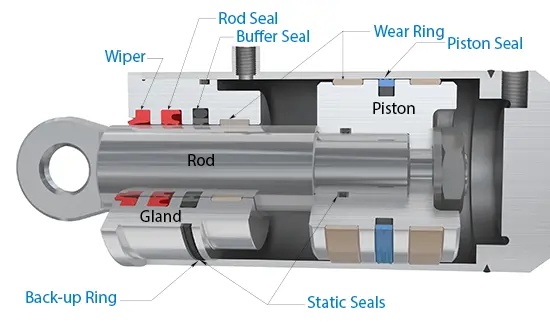

Hydraulic cylinder seals are used to seal the opening between various components in the hydraulic cylinder. They are designed to retain hydraulic fluids, exclude solid or liquid contaminants, and maintain hydraulic pressure. These tasks require a variety of different seal designs and performance-enhancing features. Seal material must conform to irregularities in metal surfaces to block fluid passage. To adjust to clearance gap size changes, the seal must expand or compress rapidly to follow dimensional variations. Finally, to resist being extruded into gaps, the seal must have sufficient modulus and hardness to withstand shear stress produced by system pressure. Successful sealing involves containment of fluid within fluid power systems and components while excluding contaminants. The surfaces in contact with a seal determine what type to use. The surface can either be static or dynamic—in motion or without movement. Static seals are typically used when there is no relative motion between mating surfaces. Dynamic seals are the opposite. They are used when there is motion between surfaces. This can be either reciprocating or oscillating motions.

Hydraulic Cylinder Rod Seals

Rod seals may have the most difficult task in sealing hydraulic cylinders because they must keep hydraulic oil from leaking into the surrounding environment while maintaining a thin coating of oil on the rod surface. Rod seals may have the most difficult task in sealing hydraulic cylinders because they must keep hydraulic oil from leaking into the surrounding environment while maintaining a thin coating of oil on the rod surface.

Rod seals act as a pressure barrier to keep the operating fluid inside the cylinder. They also provide a thin lubrication film on the piston rod that lubricates the rod seals and wiper seals. The lubricant also inhibits corrosion of the piston rod surface. However, the lubrication film must be thin enough so it returns internal to the cylinder during the return stroke. Selecting profiles and materials for a rod sealing system is a complex task, considering all possible cylinder designs and application criteria. Rod and buffer seals come in many different profiles and in a wide range of materials, series, and sizes to perform under a variety of operating conditions and applications.

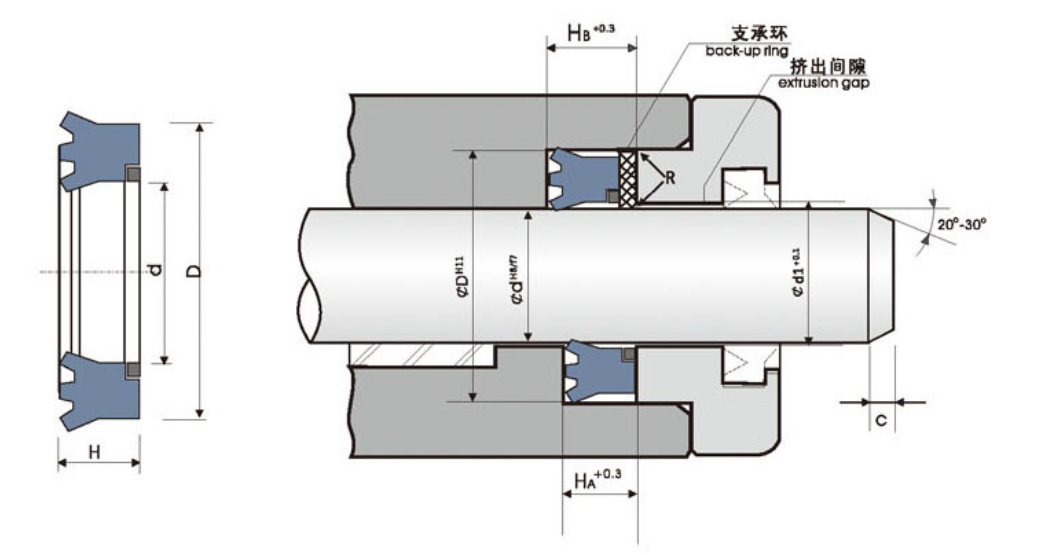

BU are made up of high performance 93 Shore A PU nutrings and POM back up rings.Designed specially for rod appllications,our BU rod nutring operate excellent by the help of POM ring in preventing the problems caused by permissible gap.

Technical Data

Pressure: ≤ 500 bar

Temperature: -35 to +110℃

Speed: ≤0.5m/s

Media: Hydraulic oils (mineral oil-based) Material

Material: PU Back-up rings:POM

Hardness: 93+/2 Shore A

Color: Turquoise

Back-up rings:Black A

Standard Size of BU Rod Seal

| Size(mm) | Size(mm) | Size(mm) | Size(mm) | Size(mm) |

| 55×70×8.5 | 70×85.1×6.1 | 85×100.5×6.1 | 110×130×11.4 | 170×190×14.5 |

| 56×71×8.5 | 70×85.5×6.1 | 90×105×8.5 | 120×140×11.4 | 180×205×14.5 |

| 60×75×6.1 | 75×90×8.5 | 90×105.5×6.1 | 130×150×14.5 | 200×225×14.5 |

| 60×75×8.5 | 75×90.5×6.1 | 95×110.5×6.1 | 140×160×14.5 | 220×250×18.2 |

| 63×78.1×6.1 | 80×95×8.5 | 100×115.5×6.1 | 150×170×14.5 | 250×280×18.2 |

| 65×80.5×6.1 | 80×95.1×6.1 | 100×120×11.4 | 160×180×14.5 | |

| 70×85×8.5 | 80×95.5×6.1 | 110×125.5×6.1 |

Contact: Betty Huang

Phone:

E-mail: diseals@aliyun.com

Whatsapp:+8617576003274

Add: No. 8, Wuxia South Third Street, QiaotouTown,City:Dongguan,Province:Guangdong,China.Post code:523540

We chat